Every product has a story. Rarely, however, do we get to hear about the people, materials, and processes involved in the product’s manufacturing. As part of Inventor’s Month, we thought we’d give you the unheard product story behind the Seatbelt Chair. Here’s how it went from an entry in theYouGoods design contest to the focal point of your living room:

On April 30th, 2010, Adam Barron’s Seatbelt Chair had just won the YouGoods Vintage Vehicle Challenge. Everyone here in the offices at UncommonGoods was in love with the chair, but one question was on our minds: How are we going to make this?

Step #1: Call the designer.

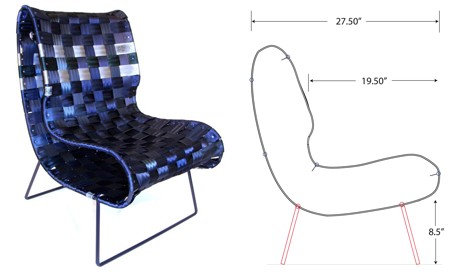

Adam’s original chair and a side-view drawing

The first thing that we did was give Adam a call and talk to him about his process in making his original chair (pictured above). Adam had visited a junkyard in Ohio to find the seatbelts and buckles, then worked with a local metal fabricator to create the frame, bent from steel rod. Being a busy student, Adam didn’t have time to serve as the artisan for multiple chairs, so we set out to make the chair in NY, armed with design specs (drawings with dimensions) and information from Adam.

Step #2: Understand the parts, materials, and processes required.

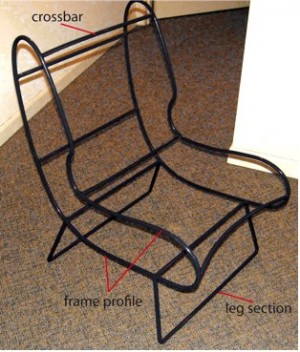

Steel frame before assembly.

The most exciting part of the product development process is seeing materials transformed into a finished product. Listing the materials and parts required gives a clue as to the manufacturing processes involved, and the type of manufacturers to contact.

STEEL PARTS (made from .5” diameter rod):

– 2 identical frame profiles

– 2 identical leg sections

– 7 steel crossbars

PROCESSES INVOLVED:

– Steel forming

– Welding

– Powder coating

Prototype seatbelt component before assembly. That’s a lot of seatbelts!

RECYCLED CAR PARTS:

– 53 seatbelts

– 8 seatbelt buckles

PROCESSES INVOLVED:

– Sourcing recycled materials

– Cutting belts to length

– Assembly

Step #3: Work with manufacturers to prototype.

Snaps used to fasten the seatbelt webbing to the frame.

While a local steel fabricator in Long Island, NY went to work creating a prototype frame, we turned to our friends at Buckle-Down, Inc, creators of the Seat Buckle Belts, for help with the seatbelt component of the chair. They searched scrapyards in NY for the highest quality seatbelts and buckles to reuse, and had suggestions for ways we could make the chair the best it could be. For example, we experimented with using snaps to fasten the seatbelt webbing to the frame of the chair, instead of screws and nuts used in Adam’s original design. We also added adjusters that would allow the end user to adjust the tautness of the lateral pieces of seatbelt webbing.

Step #4: Iterate and improve.

As you might guess, bending steel to form curves is no easy task. Making a prototype helped determine how we could improve the process for the production versions. For example, the steel fabricator ended up creating a system of tooling to ensure that each chair profile was created to Adam’s specs. We also improved the quality of the welds, and slightly modified the distance between the seatbelt snaps to allow for maximum comfort by the end user.

Step #5: Have a seat!

The final product, road-tested and ready.

5 Comments

What an interesting process. This is really a great looking chair. A work of art!

How to Make a Seatbelt Chair | the Goods | The Official Blog of UncommonGoods

Hi there, your chair looks great! I’m looking at making a similar one. Were the seatbelt snaps strong enough to hold the chair together with weight of someone sitting on it? Or would you recommend sewing/screwing them together?

Cheers

[…] Today I came across a completely different chair using seat belts. The chair is called ‘Reclaimed Seatbelt Chair‘ designed by Adam Barron. When he designed this chair in 2010 he was an Industrial Design […]

Hi Dear,

We are willing to collaboration a link on your page

https://www.uncommongoods.com/blog/2010/how-to-make-a-seatbelt-chair/

I have multiple sites regarding education,fashion,and business from these one link is for your web.

If your website gives 70 DR then i will offer upto $ 150 for link insert

If you have any query feel free to contact

Please let me know can i send you web details?

Waiting for your supportive response,

Regards,